Do you have requirements which require an automated taping & handling system? Depending upon your specific requirements, we can offer you different automated systems. Just let us know your requirements, and we will for sure find a suitable solution together!

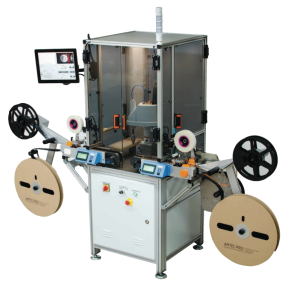

Our FlexCell systems are suitable for diverse requirements thanks to their modular design. They can be used for automatic tape & reel packaging of diverse components – from tray, tube, bowl feeder or also from tape for re-taping. Alike, they can be used for automating various processes by integrating tools for component processing such as bending, cutting, gluing, or assembling, as well as test systems; the components can then be dispensed either in tape & reel, on trays, or in other ways. Various optical inspection systems can be integrated for quality control. FlexCell systems have e.g. following features:

- Automated tape & reel machine with tray, tube, bowl or/and tape input options

- Innovative pick & place handling system

- Handles different tape widths, depending upon requirements

- Two taping modules allow use without interruption also during material change

- Possibility to rotate parts by +/-90 or 180 degree

- 3D coplanarity inspection, 3D BGA inspection, 2D vision inspection, testing, mark inspection, orientation

- Empty pocket detection as well as mechanisms for early warning of low carrier tape, low cover tape and tape advance

- Touch screen operator interface

- Universal adjustable heat and PSA sealer

- Flexibly adjustable sealing parameters

- Warning in case of high/low temperature

- Automatic leader/trailer

- Reject to tray or bulk of bin sort

- Easy settings and comfortable usage

AMTEC.PRO’s engineers have many years of experience in designing and producing tape & reel systems and automation systems. Their combination of experience and flexibility enables them to realise also specific requirements at a very good price-performance-ratio.

further information