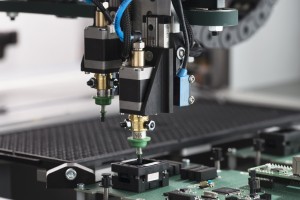

A proven taping machine combined with an automatic parts feeder at low cost – this is the table top handler.

The table top handler can automatically pack components from tray, tube or bowl feeder. It is compact, flexible, and can also be used as manual taping machine for smaller quantities.

Features

- Input options: JEDEC Tray, Tubes, Bulk Feeder, as a single choice or multiple combinations

- Output options: Tape, Tray, Tubes

- Throughput min. 800 pcs/h

- Tape width: 8-24mm

- Tape pitch: 2-72mm

- Max pocket depth: 40mm

- Electrical supply: 230VAC, 2A

- Option for office use: complete system can be Compressed Air Free

- Possibility to integrate any kind of programming / test system

- Vision sensor for component presence and orientation can be integrated

- 7” Touch Screen with Graphical User Interface

- Working parameters are stored under job files

- Testing and functionality as well as error status and history can be traced

- Additional communication with ERP systems available

- Intelligent sensing technology allows error free work without constant interference with the machine

further information

The automated Tape & Reel System “Table Top Handler” can accomodate different input media: JEDEC Tray, Tubes and Bulk Feeder, as a single choice or multiple combinations. Tape, Tray and Tubes can be used as an output.

The Table Top Handler is based upon the proven Taping Machine, which can be used also for manual insertion of the components.

For office use the complete system can be Compressed Air Free – so there is no need for additional compressed air installation which leads to significantly lower noise.

The dual Z-axis configuration allows production with higher throughput, with no idle run in configuration with programming unit or test units. In simple pick & place operation the capacity is almost doubled comparing to single head unit.

The standard pick & place nozzles allow easy and fast interchange of nozzles.

Multiple standard automated programmers can be integrated into test area. Digital Input/Output are available for interface with programmer unit, as well as any kid of TCP/IP communication. On request, compressed air or electronic opening system for programming / test sockets can be integrated.

Opening on the back side provides possibility for all possible connection needed to integrate any kind of

programming / test system.

Complete control of the system is done through 7” Touch Screen with Graphical User Interface. Working parameters are stored under job files in order to retrieve it when needed. Testing and functionality as well as error status and history can be traced. Additional communication with ERP systems is available. Integration of third party devices can be done under certain conditions.

All the taping machine functionality including intelligent sensing technology is integrated into the table top

handler. This allows error free work without constant interference by an operator with the machine. Vision sensor for component presence and orientation can be integrated to the taping module.