Features

- Automated fine-pitch IC device programming system with quad-nozzle, optimized for maximum throughput

- Short changeover time for different programming jobs

- Throughput up to 2400 devices per hour with gang 4 socket boards

- Downward CCD for pick & place position teaching and auto-teach mode

- Precisor or high-resolution upward CCD to detect the pickup offset and to align them for accurate placement

- Equipped with 4 sites (AP720) or up to 9 sites (AP760) of System General H9800 Universal Programmers

- Coupled with gang socket boards, each embedded H9800 site programs up to 4 NAND/NOR Flash, MCU or 8 eMMC Flash simultaneously at high speed

- Project manager software for full subsystem integration

- Connection to task management software with USB interface and comprehensive statistics administration

- Single, 2-, 4- and 8-socket-boards as well as T4 and S8 socket boards available

Optional:

- Tray stacker for up to 20 Jedec trays

- Tray stacker for non-Jedec trays

- Input / output media for tube and tape (tape & reel)

- Tube-in and Tape-in up to 4 simultaneously

- Ink marker at tape-out

- Label feeder

- 2D / 3D inspection

- Laser marker

further information

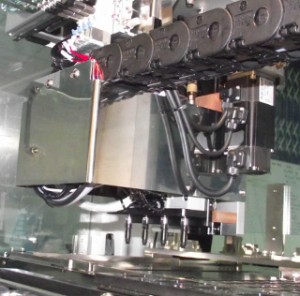

The AP720/AP760 fine-pitch automated IC device programming systems were developed with maximum flexibility and throughput in mind. Each system has a quad-nozzle and all input / output media like tray, tube and tape can be combined and are available without changeover. In addition the systems can be equipped with a laser unit for component marking, a 3D inspection module and a tray stacker for up to 20 trays. The system has 4 (AP720) respectively up to 9 (AP760) integrated H9800 universal high-speed programming stations that provide up to 16 respectively 36 available programming sockets using gang-4 socket boards. Correct placement of components is ensured either mechanically using a precisor, or optically using a CCD camera. Another feature are adjustable stepper motors for opening and closing the programming sockets.

Comprehensive user software:

The PUI software contains task management software to create pre-defined programming jobs (tasks), task version control and password protection (administrator and operator mode). The software offers any possibilities and information to configure and save tasks including serialization and comprehensive statistics administration. Created tasks can be used in APxxx automated systems, as well as in manual models T9x00(+).

The handler’s GUI contains in addition a project manager software with version control, password protection and any possibilities and information to configure and save automated programming projects. Detailed reports and statistics are stored in separate folders and can be printed for documentation immediately or later.

S4 socket boards enhance programming throughput by up to 4 times:

The 4-site S4 socket boards allow to program 4 devices at a time and thus significantly increase throughput. Also serial numbering is possible for up to 4 devices each with its own serial number. For NAND flash devices, its isolated circuitries for each socket enable independent Bad Block management for each device, which ensures the highest yields as well as the highest programming reliability.

Maximum flexibility and cost savings using the new T4 socket boards:

T4 socket boards’ new architecture increases the programming speed considerably and can raise throughput by up to 5x; considering the ever growing memory sizes of MCUs, this can bring a considerable advantage. With their flexible design they can be used with 1, 2, 3 or 4 sockets, which allows for maximum flexibility in throughput and lowest cost possible – from prototyping to mass production. Also serial numbering is possible for up to 4 devices each with its own serial number.

UFS (Universal Flash Storage, JEDEC) programming:

Iverta socket boards are the new solution for UFS programming on System General T/H9800 universal device programmers. They can also be used with 1, 2, 3 or 4 sockets to optimally adapt to throughput requirements. Support for UFS spec. versions v2.0, v2.1 and v3.0 and compliance with UFS 3.2 Gen 1 specification are just a few outstanding features to be mentioned.

And as with any System General equipment, you receive maximum flexibility at minimum cost:

Most current programming algorithms are provided free of charge for download about every six weeks. Sockets with receptacles are not proprietary. New algorithm development is free of charge. True universal programmers. Socket boards can be used on manual programmers as well as on automated APxxx programming systems.